The specific application and important role of high-voltage wiring harness in the interior of new energy vehicles

The specific application locations of high-voltage wiring harnesses in new energy vehicles include connections from battery packs to powertrains, electronic control equipment, and other high energy consuming devices.

The high-voltage wiring harness of new energy vehicles is a power transmission bridge that connects the battery pack with other high-voltage components in the vehicle. These wiring harnesses are not only responsible for transferring electrical energy from one component to another, but also for maintaining efficiency and safety in narrow and complex car interior environments. Understanding the layout of these wiring harnesses inside the car can help enhance awareness of the performance and safety of new energy vehicles.

1. Application of High Voltage Wiring Harness in the Interior of New Energy Vehicles

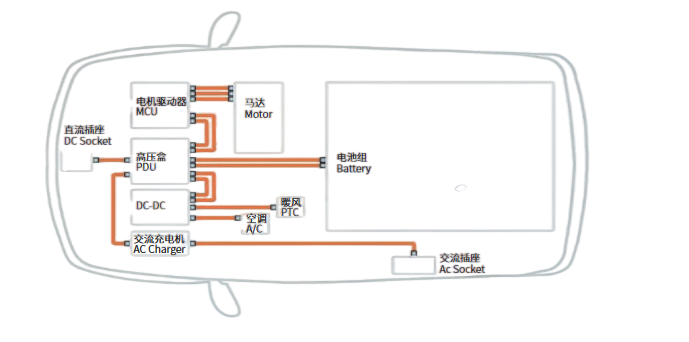

The high-voltage wiring harness of automobiles plays a crucial role in new energy vehicles, connecting the vehicle's high-voltage electrical system to ensure effective transmission of electrical energy. Through detailed illustrations, we discovered how the highlighted high-voltage wire harness precisely connects various key components tightly.

SAILTRAN GROUP's automotive high-voltage wiring harness connections mainly cover the following aspects:

1. Connection between high-voltage distribution box (PDUQ) and DC socket: This is a crucial step in the charging process of electric vehicles, ensuring that electrical energy flows smoothly from the charging port to the battery pack.

2. Connection between Motor Driver (MCU) and Motor: This connection ensures that the motor can receive stable electrical energy to output the required power.

3. Connection between Motor Driver Unit (MCU) and High Voltage Distribution Unit (PDU): This connection ensures efficient flow of electrical energy between the motor controller and the distribution unit.

4. Connection between High Voltage Distribution Unit (PDU) and Battery Pack: Connecting the battery pack and distribution box is the core part of energy distribution and management.

5. Connection between High Voltage Distribution Unit (PDU) and DC/DC Converter: The DC-DC converter is responsible for converting high voltage electrical energy into low voltage for use in the vehicle's low voltage electrical system.

6. Connection between High Voltage Distribution Unit (PDU) and AC Charging Machine: This connection allows electric vehicles to be charged through AC charging stations.

7. Connection between AC charger and AC socket: provides a convenient charging method for electric vehicles, enabling them to use external AC power supply system for energy supply. 8. Connection between DC-DC converter and heating PTC: ensures stable power supply for the heating system of electric vehicles.

In summary, SAILTRAN GROUP's automotive high-voltage wiring harness has built a complex and efficient electrical energy transmission network within new energy vehicles. These wiring harnesses not only ensure the smooth transmission of electrical energy, but also ensure the safe and reliable operation of the entire electrical system.

2. Below is a detailed discussion on the important role of high-voltage wiring harnesses in the internal application of new energy vehicles

1. High voltage wiring harness connecting the battery pack to the charging interface: Typically, this part of the wiring harness needs to have high voltage and current carrying capacity to ensure that short circuits or overloads do not occur during the charging process.

2. High voltage wiring harness for internal connections of battery pack: Within the battery pack, various battery modules or units also need to be connected through high-voltage wiring harnesses to ensure effective combination and distribution of battery energy. These wiring harnesses usually need to be designed to be more flexible and durable, able to work stably in the internal environment of the battery pack.

3. High voltage wiring harness connecting the battery and powertrain: The energy of the battery needs to be transmitted to the motor controller through the high-voltage wiring harness to drive the motor to work. This wire harness usually needs to have excellent high temperature resistance and mechanical protection to prevent damage caused by high temperature or vibration during motor operation.

4. The high-voltage wiring harness connecting the battery to high energy consuming devices: for example, the connection between the battery and the air conditioning compressor is also completed through the high-voltage wiring harness. This type of wiring harness not only needs to be able to carry large currents, but also needs to have good wear resistance and corrosion resistance to adapt to complex and changing working environments and extend its service life.

In order to ensure the safer and more reliable application of automotive high-voltage wiring harnesses in new energy vehicles, SAILTRAN GROUP's R&D engineers fully consider various complex factors in the design process, ensuring that automotive high-voltage wiring harnesses are resistant to high temperatures, wear, electromagnetic interference, etc., to ensure the performance and safety of the entire vehicle.