IEC 62893-2020 EV charging cable application

It is mainly used for the connection between the AC or DC electric vehicle charging pile and the electric vehicle, and can also be used for the connection between the portable charging device and the charging power source.

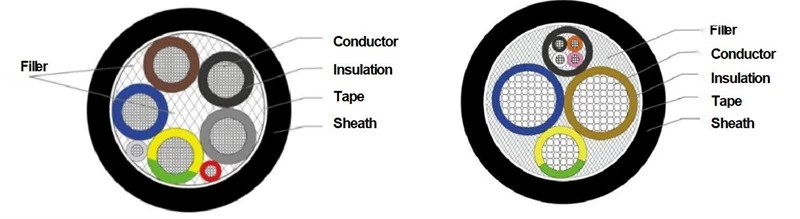

IEC 62893-2020 EV charging cable product structure

Conductor: multi-strand fine-stranded conductor, in line with the standard of category 5 or category 6 in IEC 60228

Insulation: irradiated ethylene propylene rubber, color can be customized according to customer requirements

Shielding (if any): braided copper wire and wrapped with aluminum-plastic composite tape

Filling: PP mesh filling rope

Tape: thin non-woven fabric

Sheath: TPU, Color: Black

IEC 62893-2020 EV charging cable technical parameters

Rated voltage: AC 450/750V and below, DC 1500V and below

Hipot test: 2.5kV/5min, 3.5kV/5min

Conductor working temperature: -40℃~+105℃

Working environment temperature of the product: -50℃~+50℃

Minimum bending radius: 4D for static applications; 5D for dynamic applications

IEC 62893-2020 EV charging cable technical feature

Resistance to chemical liquids: IEC 62893 (pass test for: liquid lubricating oil, diesel and gasoline for high-load machinery, unleaded gasoline, urea, diesel, antifreeze and cleaning solvents)

Anti-ultraviolet aging: IEC62893, no discoloration, no cracking, retention rate of tensile strength and elongation at break ≥70%

Friction resistance: IEC 62893 (the sheath is reciprocated and scraped 2000 times, the sheath will not be worn through, and the core will not be exposed)

Low temperature bending: IEC 62893 (-40℃/16h, no cracks on the cable surface)

Anti-vehicle crush: meet the requirements of IEC 62893

Flame retardant performance: meet the requirements of IEC 62893

Halogen-free: meet the requirements of IEC 62893

Meet RoHS

AC & DC Electric Vehicle Charging Cable Structure Diagram

Parameters of IEC 62893-2020 EV Charging Cable

| Model | Cable Specifications(mm²) | Conductor outer diameter(mm) | Finished outer diameter range(mm) | 20℃ Conductor Maximum DC Resistance(Q/kM) | Reference ampacity(A) |

| Cable structure and electrical parameters for AC electric vehicle charging | |||||

62893 IEC 121 62893 IEC 123 | 3×2.5+(0~2)×(0.5~0.75) | 2.3 | 12.0~13.0 | 7.98 | 20 |

| 3×6+(0~2)×(0.5~0.75) | 3.5 | 15.0~16.0 | 3.3 | 32 | |

| 5×2.5+(0~2)×(0.5~0.75) | 2.3 | 14.0~15.0 | 7.98 | 20 | |

| 5×6+(0~2)×(0.5~0.75) | 3.5 | 19.0~20.0 | 3.3 | 32 | |

| Cable structure and electrical parameters for DC electric vehicle charging | |||||

| 62893 IEC 126 | 2×16+1×16 | 5.8 | 19.0~22.0 | 1.21 | 80 |

| 2×35+1×25 | 8.6/6.9 | 27.0~32.0 | 0.554/0.780 | 125 | |

| 2×50+1×25 | 10.0/6.9 | 32.0~37.0 | 0.386/0.780 | 150 | |

| 2×70+1×25 | 11.8/6.9 | 37.0~42.0 | 0.272/0.780 | 250 | |

Get Your Sample

If you are interested in our products, please feel free to send an email to info@sailtran.com or fill out the message form below. Our sales representative will contact you within 24 hours.