IEC 62893-4-2 Liquid-cooled EV charging cable application

Products are IEC 62893-4-2 compliant and certified to IEC 61851-1 Mode 4 for use with thermal management systems; these cables are intended for conductive charging in circuits with thermal management systems specified in the IEC 61851-23 system , and used in vehicle connectors that meet the requirements of IEC TS62196-3-1.

It is mainly used for the connection between the DC electric vehicle charging pile and the electric vehicle, and it can also be used for the connection between the portable charging equipment and the charging power source.

The cable structure is mainly composed of the main core of power supply, ground wire, signal wire or shield wire set, return pipe, filler and reinforcing rope combination. DC+ and DC- conductors are immersed in the cooling medium to take away heat through the medium and form a cooling circuit through the circulation of the return pipe, which eventually carries a larger current with a smaller conductor cross-section to achieve the effect of high-power fast charging; the product feels good, oil-resistant, acid-alkali-resistant, water-resistant and wear-resistant. Acid and alkali resistant, water resistant, wear resistant, crush resistant, crack resistant, UV resistant and flame retardant; all materials comply with RoHS 2.0 & REACH environmental standards.

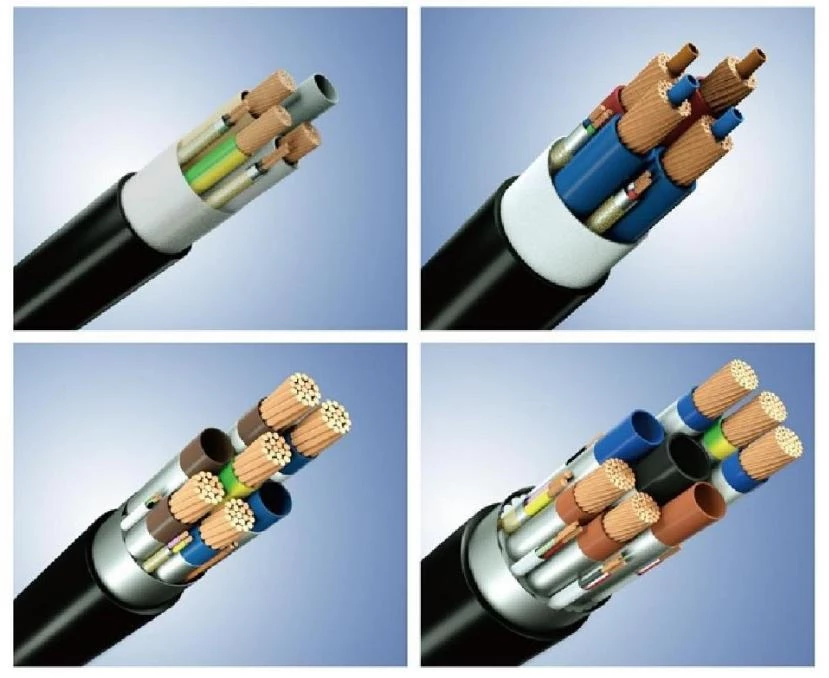

IEC 62893-4-2 Liquid-cooled EV charging cable product structure

Conductor: multi-strand fine-stranded conductor, in line with the standard of category 5 or category 6 in IEC 60228

Insulation: Irradiation cross-linked polyolefin, color can be customized according to customer requirements

Shielding (if any): braided copper wire and wrapped with aluminum-plastic composite tape

Filling: PP mesh filling rope

Tape: thin non-woven fabric

Sheath: TPU, color one black

IEC 62893-4-2 Liquid-cooled EV charging cable technical parameters

Rated voltage: DC 1500V and below

Hipot test: 3.5 kV/5min

Conductor working temperature: -40℃~+105℃

Working environment temperature of the product: -50℃~+50℃

Minimum bending radius: 4D for static applications; 5D for dynamic applications

IEC 62893-4-2 Liquid-cooled EV charging cable technical feature

Resistance to chemical liquids: IEC 62893 (pass test for: liquid lubricating oil diesel and gasoline for high-load machinery, unleaded gasoline, urea, diesel, antifreeze and cleaning solvents)

Anti-ultraviolet aging: IEC62893, no discoloration, no cracking, retention rate of tensile strength and elongation at break ≥70%

Friction resistance: IEC 62893 (the sheath is reciprocated and scraped 2000 times, the sheath will not be worn through, and the core will not be exposed)

Resistance to simethicone oil: (150°C, 7d) the change rate of tensile strength and elongation at break is not more than ±20%

High temperature and pressure explosion resistance: 90℃, 7bar (including coolant) liquid cooling tube will not break

Low temperature bending: IEC62893(-40℃/16h, no cracks on the cable surface)

Anti-vehicle crush: meet the requirements of IEC 62893

Flame retardant performance: meet the requirements of IEC 62893

Halogen-free: meet the requirements of IEC 62893

Meet RoHS

Parameters of IEC 62893-4-2 High-power liquid-cooled EV charging cable

| Cable Specifications(mm²) | Finished outer diameter range(mm) | 20℃ Conductor Maximum DC Resistance(Q/kM) | Reference ampacity(A) |

| 2*25+1*25+(2*0.75)P2+2*0.75+2*2*0.75 | 31.0~32.0 | 0.780/26.0 | 500 |

| 2*35+1*25+2*1.5+(2*0.75)P2+6*0.75 | 35.8~36.8 | 0.554/0.780/13.3/26.0 | 500 |

| 4*20+1*4+2*0.75+2*0.75P2+10*0.5 | 27.0~28.0 | 0.954/4.95/26.0/39.0 | 500 |

Get Your Sample

If you are interested in our products, please feel free to send an email to info@sailtran.com or fill out the message form below. Our sales representative will contact you within 24 hours.